When it comes to specifying a metering pump system, selecting the right motor type can be just as critical as choosing the pump itself. At JAECO Fluid Systems, we offer a range of motor options, including electric, gas, and belt-driven, to ensure our chemical metering pumps and dosing pumps perform efficiently and reliably, regardless of the type of metering pump required.

Each motor type has unique strengths, trade-offs, and ideal use cases. In this article, we’ll break down the differences between electric vs. gas vs. belt-driven metering pumps, focusing on energy efficiency, maintenance, operating environments, and overall cost of ownership. Whether you're designing a new system or upgrading an existing one, understanding these variables will help you make the best choice for long-term performance.

Electric Motors: Clean, Efficient, and Easy to Control

Electric motors are the most common and widely used type across JAECO’s diaphragm and plunger pump models. Available in single-phase, three-phase, and DC configurations, they offer precise speed control and are easy to integrate with automated systems.

Advantages:

- Energy Efficient: Electric motors convert power to mechanical energy with minimal loss, making them ideal for continuous-duty applications.

- Low Maintenance: With fewer moving parts and no fuel system, electric motors are relatively easy to maintain.

- Cleaner Operation: No emissions or fuel handling, ideal for enclosed spaces or environmentally sensitive settings.

- Control Compatibility: Can be easily paired with variable frequency drives (VFDs) and remote monitoring systems for more precise dosing.

Drawbacks:

- Requires Reliable Power Supply: Not suitable for remote sites without stable electricity.

- Startup Costs: May involve higher upfront installation costs depending on the electrical infrastructure.

Best For:

- Water and wastewater treatment facilities using JAECO FRAM diaphragm metering pumps for precise, leak-free chemical dosing

- Food and beverage production

- Cleanroom and pharmaceutical applications

- Municipal projects with BABAA requirements

Gas-Powered Motors: Mobility and Independence

Gas motors provide an independent power source, making them a go-to option for agricultural operations, temporary field setups, or anywhere grid power is unreliable or unavailable. JAECO offers gas motor options across both diaphragm and plunger pump configurations.

Advantages:

- Portable and Self-Powered: Useful in off-grid environments where electricity is not accessible.

- High Torque (Non-Adjustable): Gas motors are designed to provide high torque, which is ideal for driving pumps in rugged conditions. However, adjusting the torque would impact the accuracy of fluid metering, so it remains constant for precise dosing.

- Versatile Deployment: Can be set up quickly in remote or mobile installations.

Drawbacks:

- Fuel Dependence: Requires regular refueling and fuel storage, which can introduce safety and logistical concerns.

- Higher Maintenance: More moving parts and exposure to outdoor conditions increase the need for servicing.

- Environmental Impact: Generates emissions and may not comply with stricter environmental regulations.

Best For:

- Agricultural chemigation and fertigation using JAECO AGRI-FRAM or JAECO AGRI-PAK pumps in remote or off-grid environments

- Temporary or remote construction sites

- Backup systems in case of power outages

Belt-Driven Motors: Flexible and Cost-Effective

Belt-driven motors use a system of pulleys and belts to transfer energy from the motor to the pump. These systems are typically powered by another piece of agricultural equipment that has a rotating component, such as a tractor or other machinery. This setup allows for greater flexibility in motor placement and torque adjustment. Belt-driven systems are available across JAECO’s pump lines and can be combined with either electric or gas motors, depending on the need.

Advantages:

- Customizable Speed and Torque: Pulleys can be swapped out to adjust the pump’s performance characteristics without changing the motor.

- Flexible Installation: Allows motor placement in locations with space or ventilation constraints.

- Economical Repairs: Belts and pulleys are inexpensive and easy to replace.

Drawbacks:

- More Moving Parts: Introduces wear-prone components like belts that require regular inspection.

- Exposure Risk: In harsh environments, open belt systems may need guarding or shielding.

- Alignment Sensitivity: Improper belt tension or alignment can lead to premature wear or reduced efficiency.

Best For:

- Chemical processing with fluctuating demands

- Agricultural applications where pump placement is constrained, such as in mobile or field-based setups powered by agricultural equipment.

- Low to moderate-volume applications that require flexible torque adjustments without high-volume or high-torque needs, using JAECO pumps for precise dosing in industrial or municipal systems.

Comparing Electric vs. Gas vs. Belt-Driven Metering Pump Motors

When selecting the right system for your application, it helps to have a clear, side-by-side view. Below is a breakdown comparing metering pump motors, electric, gas-powered, and belt-driven, across the performance factors that matter most, from energy use to maintenance to environmental fit.

| Feature | Electric | Gas-Powered | Belt-Driven |

| Power Source | Grid Electricity | Gasoline | Powered by another piece of equipment (e.g., tractor) |

| Energy Efficiency | High | Moderate | Moderate to High |

| Maintenance | Low | High | Moderate |

| Operating Environments | Indoor, controlled | Outdoor, remote | Flexible (space-saving) |

| Initial Cost | Moderate to High | Low to Moderate | Low |

| Best Fit | Municipal, Cleanroom | Agriculture, Remote | Agriculture, Mining, Mobile, or Field-based Systems |

Impact on Metering Pump Performance

The choice of motor directly affects a pump’s reliability, dosing accuracy, flow rates, and overall pump capacity. For example:

- A diaphragm pump powered by an electric motor is ideal for sodium hypochlorite injection in a 24/7 municipal water plant.

- A plunger pump paired with a gas motor excels in delivering precise fertilizer dosing on a remote sod farm.

- A belt-driven system allows fine-tuned chemical injection in a manufacturing plant without changing the existing motor setup.

These motor-pump combinations are not just about powering the system—they influence variables like stroke length, feed rate, and turndown ratio, all of which impact how reliably and efficiently your process runs over time.

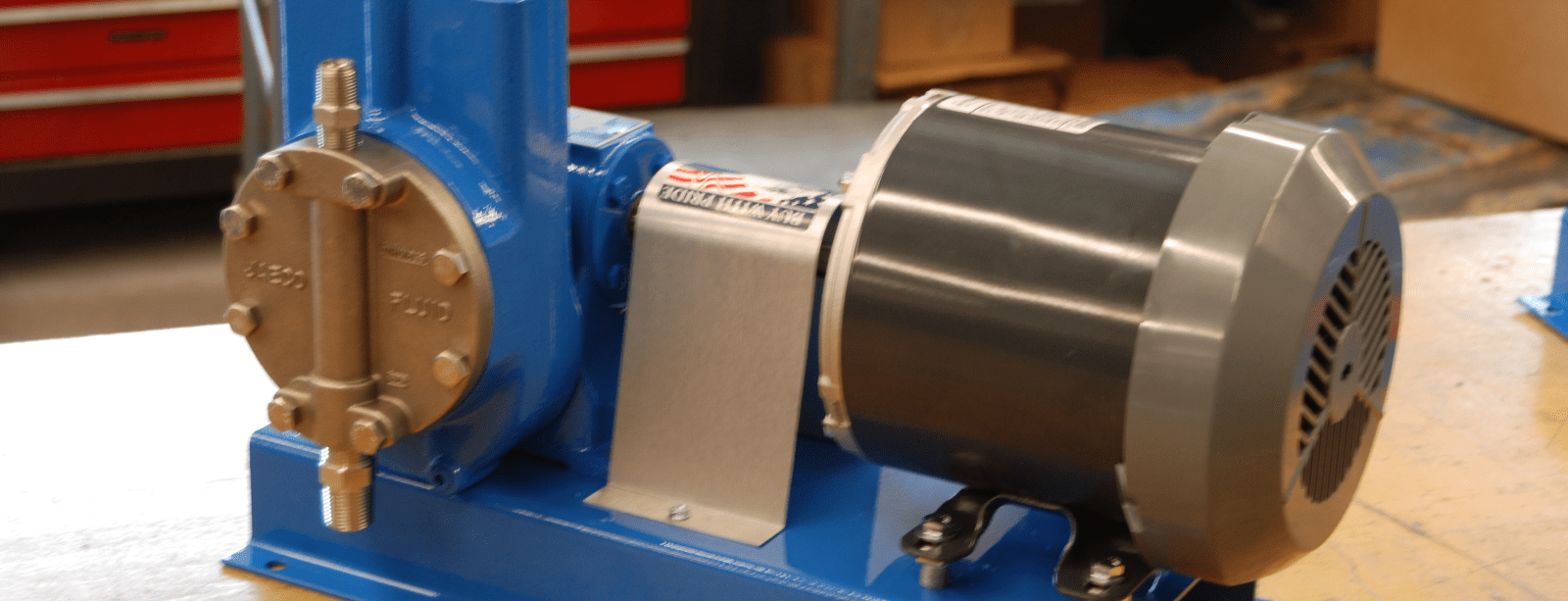

Flexible Motor Options, One Trusted Pump Partner

At JAECO, we understand that no two installations are the same. That's why we offer customizable motor configurations, electric, gas, and belt-driven, across our full line of diaphragm, plunger, and Hi-Flo metering pumps.

Every pump is built, tested, and supported from our U.S. headquarters in Pennsylvania, ensuring quality, compliance, and long-term reliability—one of the many reasons why a made-in-the-USA metering pump is the best choice.

Whether you're injecting pH adjusters into a municipal system, pumping corrosive chemicals in an energy plant, or managing nutrient delivery on a farm, JAECO supports a wide range of industries and installations with flexible solutions. Many configurations include components made from stainless steel and other corrosion-resistant materials to withstand aggressive fluids and harsh environments.